RMC Type'b' Loyal Cycle Project

|

The Connecting Rod. What can I say, not exactly the most glorious piece, but it presented a challenge since I don't have a

ball turner for my lathe. I really like the look of the conrod as it's drawn though. What to do.....? I had thought about a 3

piece conrod, but it was simpler to make it 2 pieces because I wanted brass for the end that connected to the flywheel.

|

|

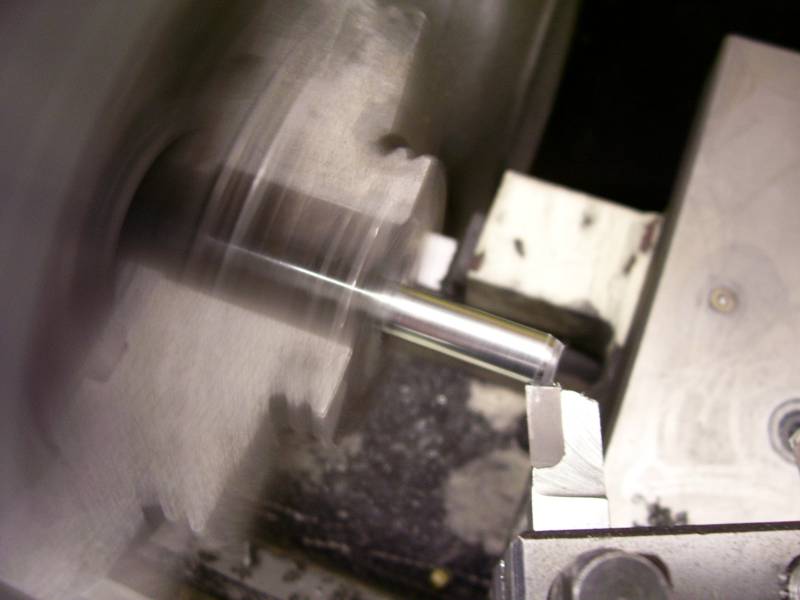

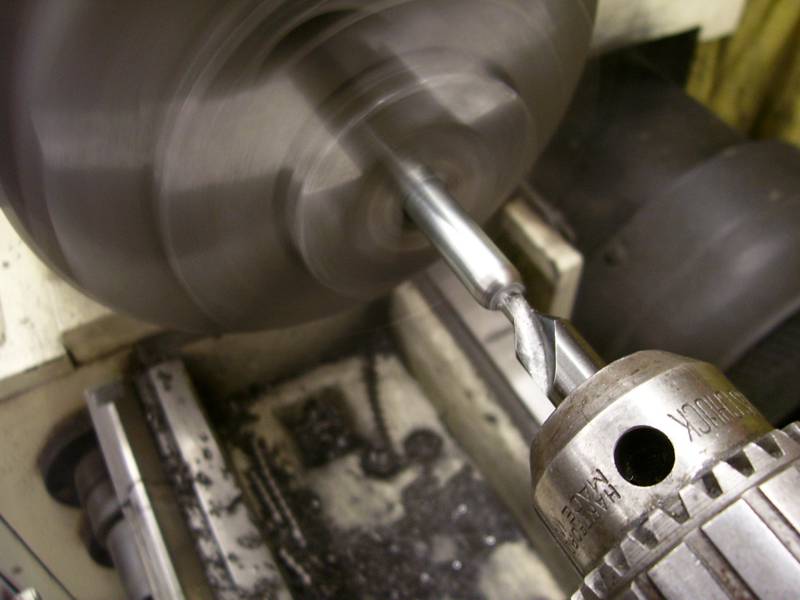

Since I don't have a ball turner, heres how I make the small ball end. First I start with a piece of rod chucked up and

I take a 45 deg or so cut

|

|

Next I change the angle on the bit and rough in another cut

|

|

Another angle and another cut. Are you starting to get the idea?

|

|

Apply a lite file to the rough cuts and you get what kinda looks like a round end

|

|

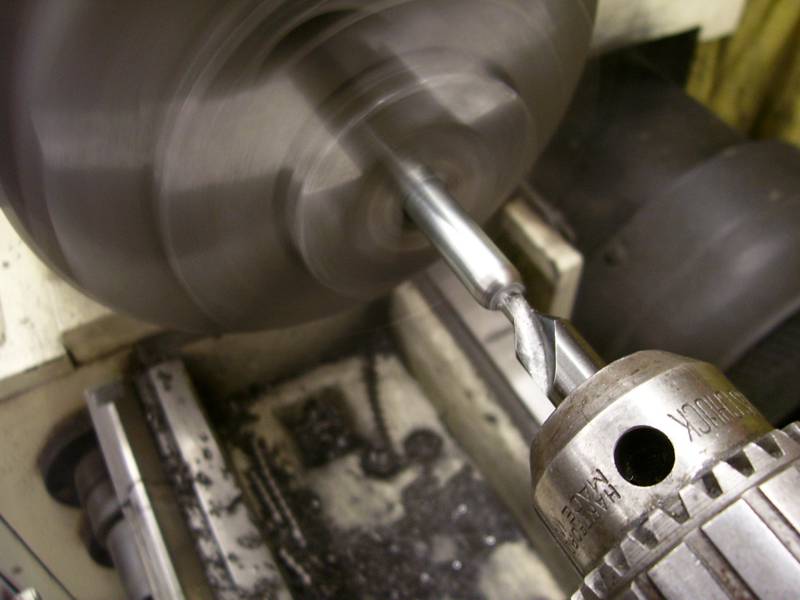

I want to turn the shank to diameter so I center drill the end (you have to drill it later anyway)

|

|

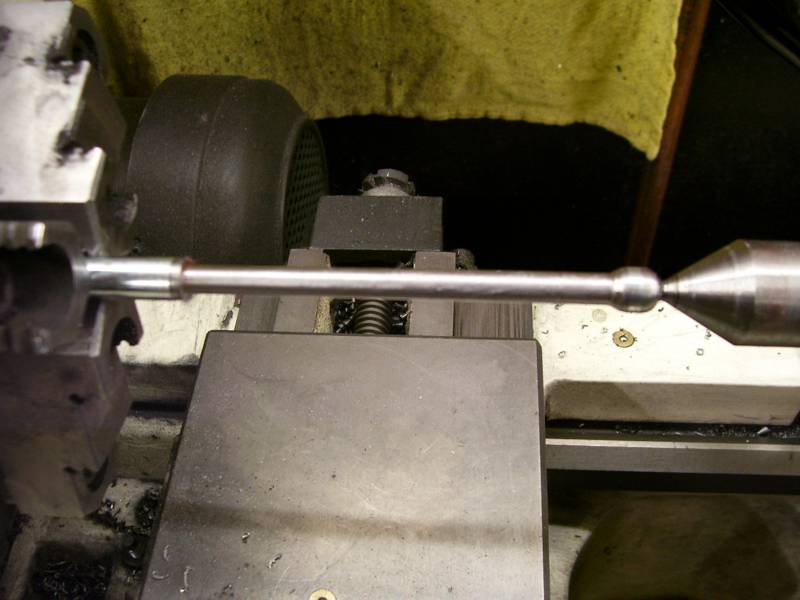

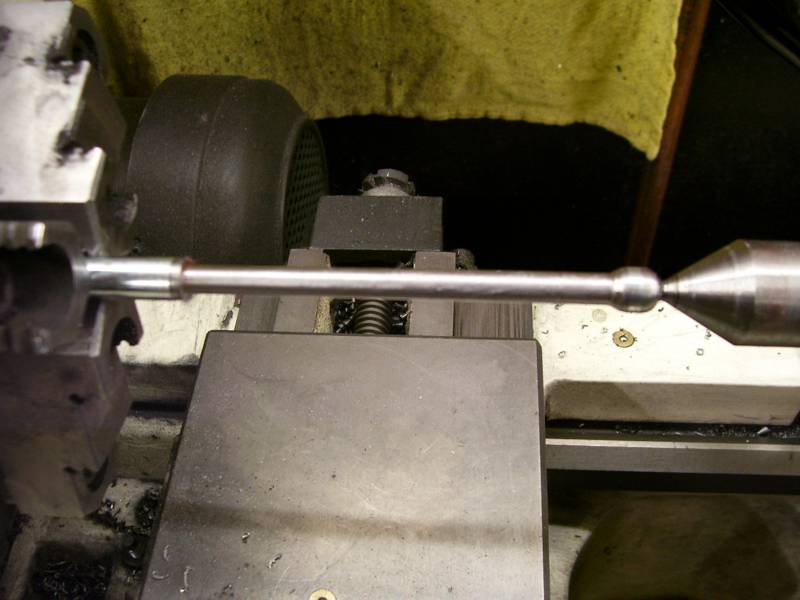

Move the tailstock and center over and get ready to turn the center shank down.

|

|

The center is finished to size. I left mine at .250" so I can thread it for the end piece, and to give a little more rigidity since it

is a multiple part conrod. Notice that I stopped the cut a little long so I have more of an oval than a ball at the end.

|

|

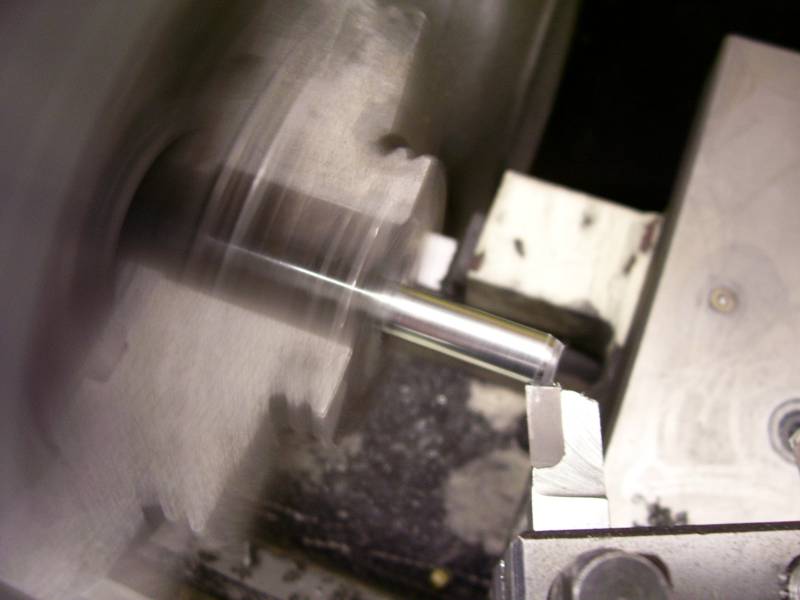

Once again, I'm starting with appx a 45 deg angle cut on the 'ball'

|

|

Change the angle and cut again

|

|

Apply a lite file once you have the shape about right and now we have a 'ball' end on our shank

|