RMC Type'b' Loyal Cycle Project

|

Time to machine the piston. I honed the cylinder until it was smooth sided, and then ball honed it for a nice cross-hatch.

I then took interior measurements of the cylinder to figure out the piston diameter. This way the piston will fit the cylinder

with the right amount of clearance.

|

|

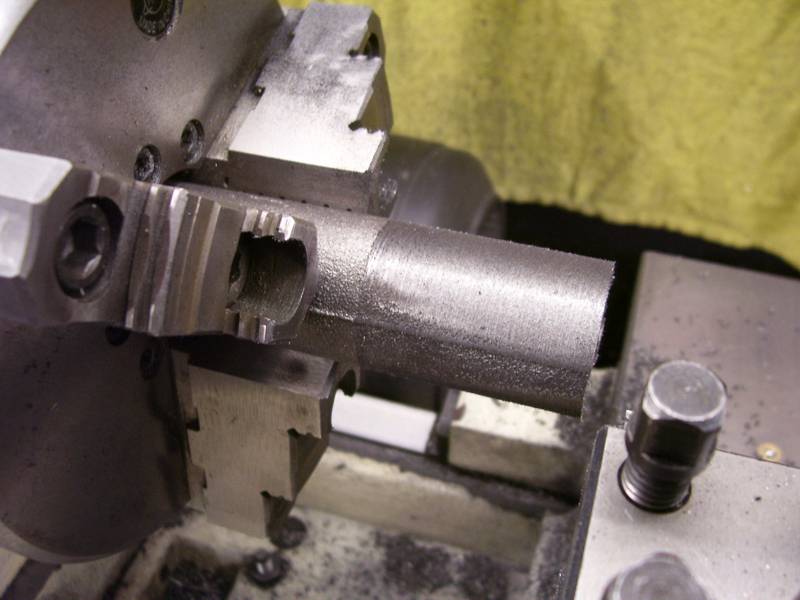

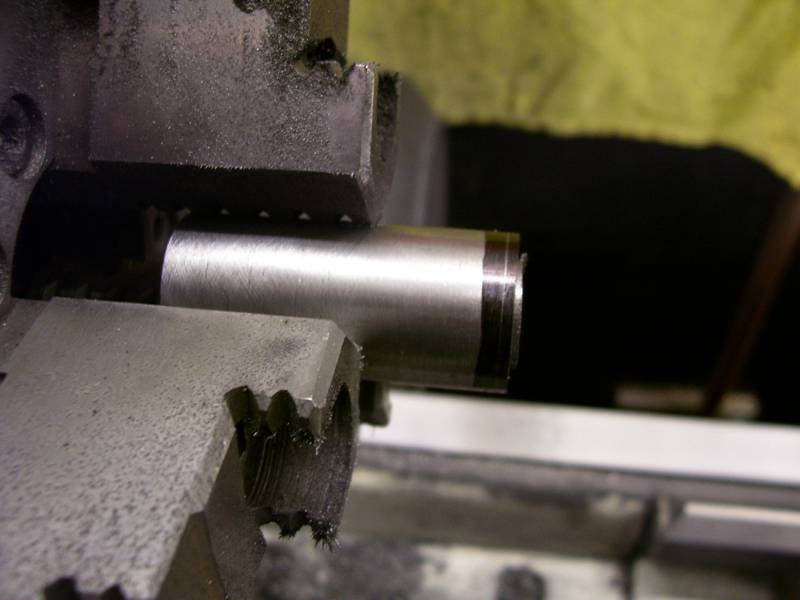

The castings that is cut off of the main body is chucked up in the 3 jaw and trued for appx 2 inches

|

|

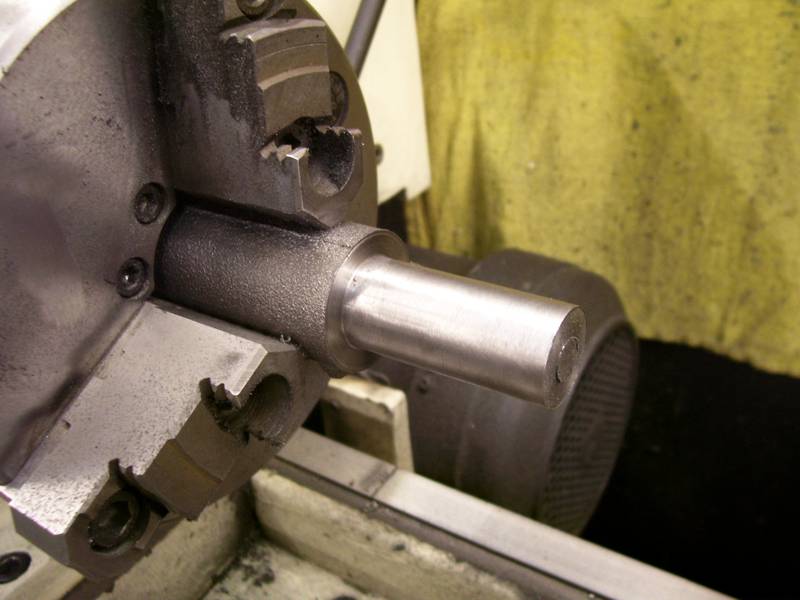

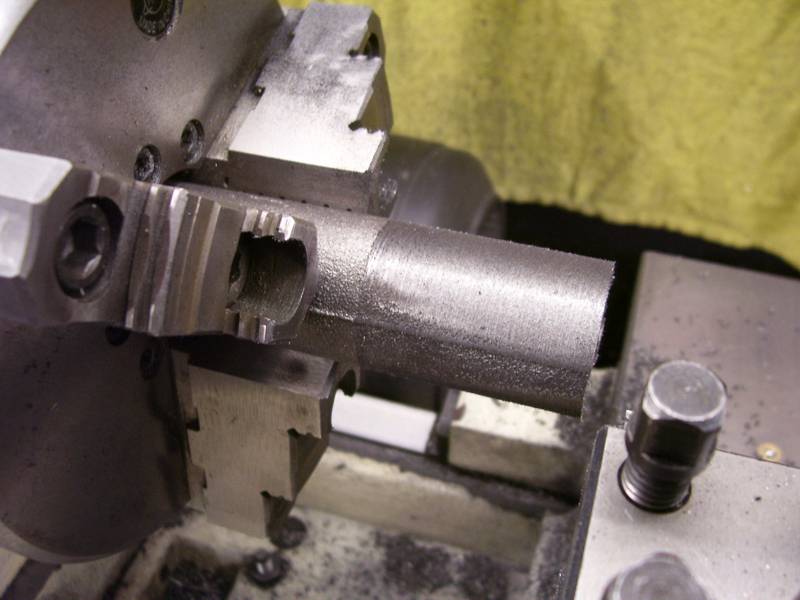

Turned to .003" over the final diameter, then filed smooth down to appx .0005" over and finished with emery paper held over a flat file

|

|

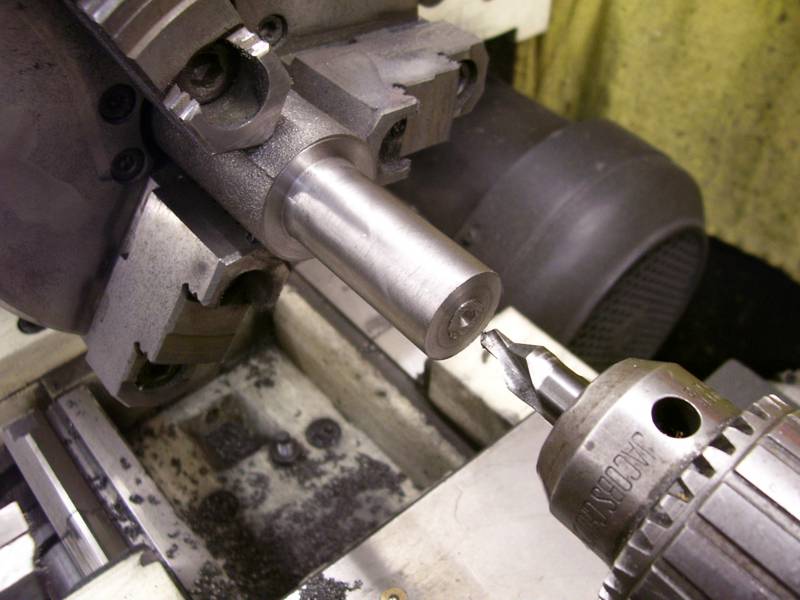

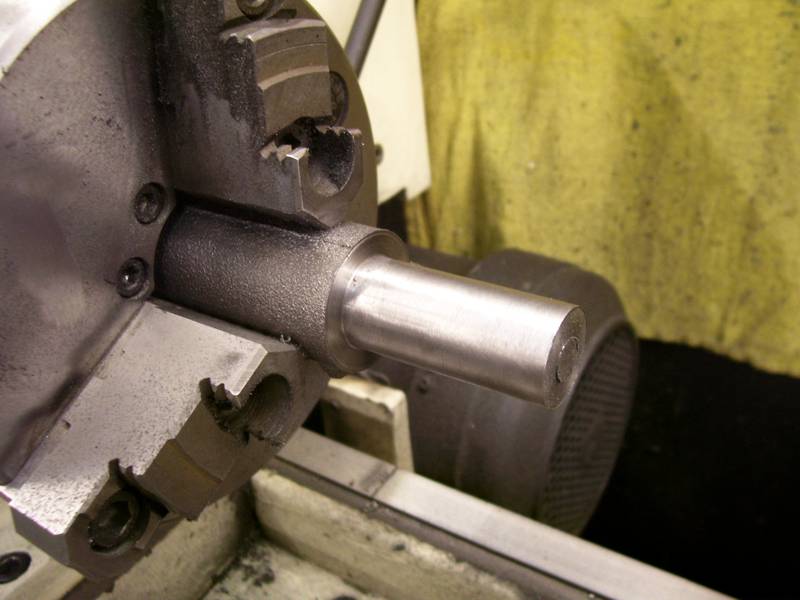

Center drill the end that will be hollowed

|

|

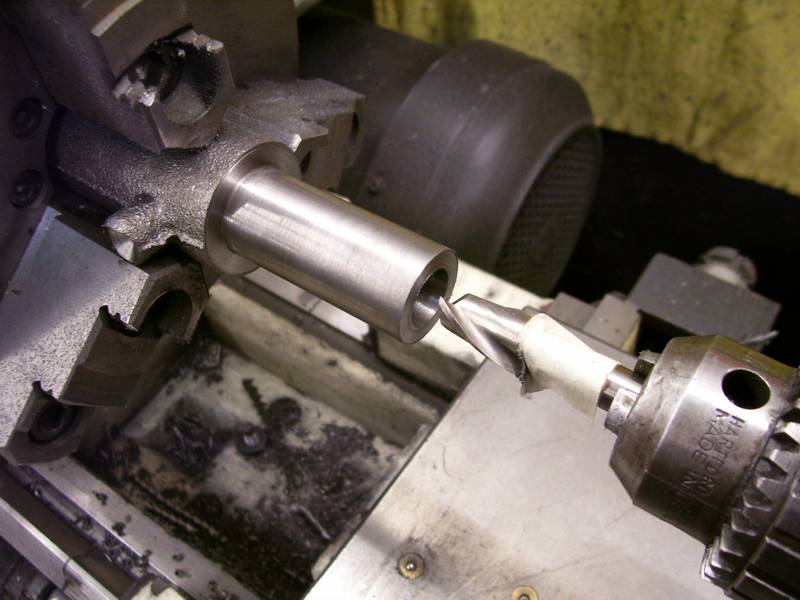

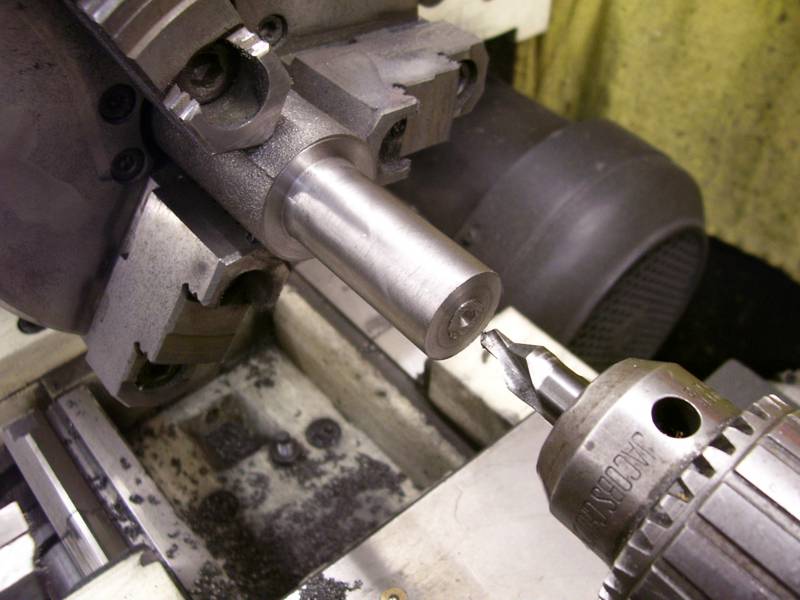

I used a drill to remove the majority of the metal, since everything is true at this point. Notice the expensive masking tape

'drill stop' I use?

|

|

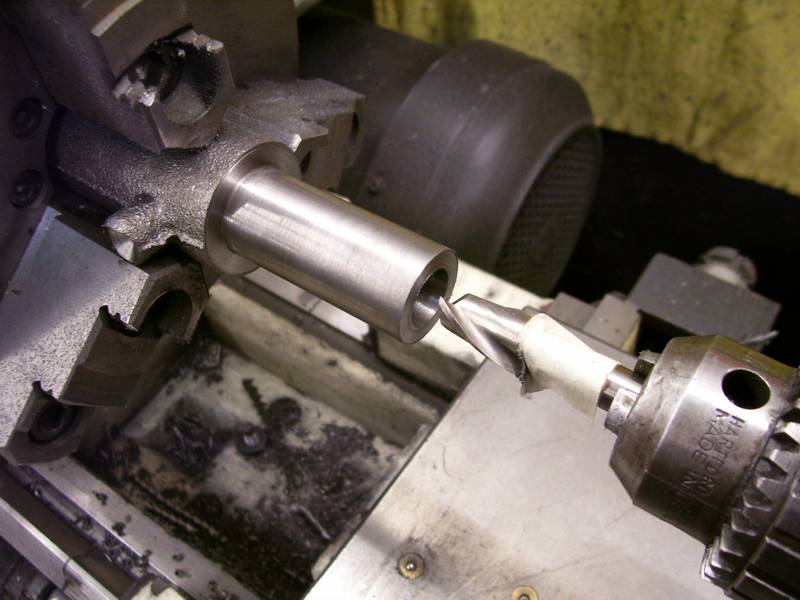

Next I chucked up the proper sized end mill to flatten the bottom of the hole. *NOTE* - Yes, I know that putting end mills in

chucks ruins the chucks. It is by gaining that knowledge that I have old beat-up chucks to put end mills in and do this kind of work. So if

you are going to follow this example, use an old chuck you don't like or you will soon have a chuck that won't center properly.

|

|

The blank piston to this point parted off

|

|

The wrist pin hole has been drilled using a floor drill and a v-grip vise, since there isn't any need to referance any other part yet

I drilled it on the center and will referance other cuts from the wrist pin alignment. It was then transferred to the rotary table

to drill the wrist pin retainer hole seen in the top surface

|

|

Now the piston has to be reduced to the proper length to proceed. I used my favorite marking dye (black permanent marker) and then

scribed the length line using my digital calipers and dragging the jaw point around the piston blank. This leaves a line that

is easily visible when the part is being turned by the lathe.

|

|

The exhaust port is next. I drilled it in the drill press again and the transferred it to the mill. I should have taken the time to set the

rotary table up vertically, but I didn't. Instead I eyeballed the angle using a drillbit through the wrist pin holes and the slot is cut slightly

off, my goof and we will see how it effects how the engine runs later.

|

|

Drilling the exhaust transfer port, take some time to align the path of the drillbit with the hole it has to meet. I usually do this by moving the part

mounted in the vise to the back of the mill just enough for the drill to drop in front of it and double check that all things line up.

|

|

The intake port is cut

|

|

Spark plug clearance is cut.

|

|

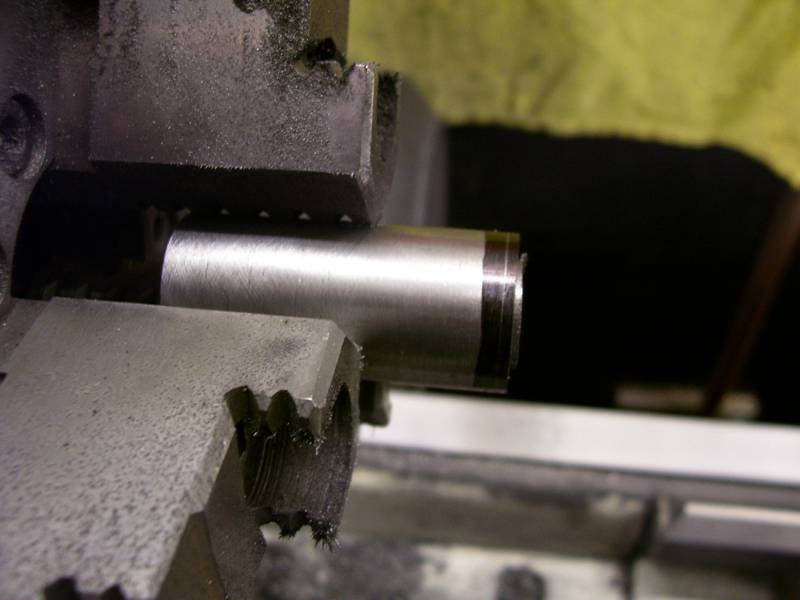

Finally, the o-ring seat is cut using a parting off tool. Mine wasn't wide enough to do the whole slot at once, so I had to cut

to depth and then move over and trim the edges until it was the right size.

|